For those that want to convert to hydroboost brakes, this is intended to be a 'how-to', including a couple variables like front disc/rear drum, front disc/rear disc. I'll update the first page as replies come in. This is not a pro-con article (would or would not, should or should not) and I'd like to disuade replies to that affect. However factual how-to (how-to or how-not-to) input is good to go.

For this article I'll presume the truck being upgraded is a 72-93 Dodge/plymouth. Now, I haven't actually done this conversion, yet, but it's in the works. So while I cannot guarantee everything will work exactly as it is writen here I'm reasonably sure those that have done this in the past (and where I got this info from in the first place) will say it does in deed work like a champ.

First off, hydroboost systems are not a custom aftermarket item - they are factory braking systems on many 90s and newer Chevy trucks and if I understand right many later 2nd gen Dodge trucks 97? and up.

Alright, so what is hydroboost? Very simply it is hydraulic brakes, using pressure from the power steering pump. Our trucks come with vacuum-assist brakes via the brake booster - well the hydroboost unit essentially replaces the vacuum booster. The typical net effect is an increase in braking pressure, sometimes dramatic, resulting in a large increase in braking. Most folks that convert over from vacuum report decreased pedal effort and very good braking - not something we often hear about from a big heavy Dodge.

The drawback is, the power for your brakes comes from your power steering pump - so long as your pump is operating you will have power. Lose the belt for it and you full-Flintstone for your brakes. The diesel guys have the bonus because the power steering pump is gear-driven off the engine, so as long as the engine is running you gots brakes.

For the purposes of conversions, the best overall system seems to be using a complete Chevy hydrobooster/master cylinder system, with the newer Dodge power steering pump.

Dodge power steering pump sends hydraulic hi-pressure to the Chevy hydrobooster brake unit, then the hi-pressure returns from the HB unit to the Dodge power steering box. Both systems get full hydraulic hi-pressure, and those lines must be rated for hi hydraulic power steering pump pressure.

The hydroboost unit and the power steering unit both require return lines, both low pressure, and those two lines can be tee-d into each other and run back to the power steering pump.

That's the bolt-up stuff; now for the voodoo.

The Chevy and Dodge hydroboost units do not bolt up to the 1st gen Dodge firewalls - an adaptor plate must be made. The only reference I have for this is from other sources at DTR, 1stGen, and I'll post up those pics as soon as I am able. As well, I plan to install the HB system in my own rig, and I will do a full write-up when I do, hopefully by Aug 09 - a month from now.

Parts needed:

- Hydroboost unit - 1990 1 ton chevy c/k30 (You will need a junkyard unit for the core, the internal spring mechanism, and the mounting bracket)

- Master cylinder - 1991 chevy k30 (1 ton) with heavy duty brake option "JB8 hydroboost"

- Power steering pump - 2000 dodge power steering pump - this unit had an additional return, has larger internal bearings and will bolt to our vacuum pump, use locktite on the 10mm studs and nuts!

For you 4-wheel disc troops, use the following HB unit and m-cylinder -

- 2003 Chevrolet 1 ton truck

**************************************************************

The following is a list of exerpts from various websites - I used these to generate the how-to thus far.

The lower relief pressure on the OE pump won't hurt anything in normal operation, the booster just won't produce as much boost at the top end. As long as you have enough pressure output from the M/C to drive the front wheels to lock you're ok. Where you might want the extra pressure would be if you had some mondo big tires or were loaded really heavy.

From what I understand, all hydroboosts are basically the same with the exception of some changes to the spool and pilot valves which control sensitivity and apply rates. Also the size of the accumulator (this holds pressure to give assist if the engine quits) varies depending on who the unit was sold to. The things that very per OE application are the mounting plate that clocks the unit on the fire wall, the stud spacing on the M/C end, the input rod length and pin diameter and sometimes the hose fittings. Since it's a custom install that needs fabrication anyway, dealing with this stuff is not too hard. I would suggest that when you source one, either new or used that you get the M/C that corresponds to the application that the booster comes from. That way the stud spacing and pin depth will match. Be aware that the second gen Dodge booster requires a spacer plate on the booster output end to correctly clock the M/C. I don't know if this is true for the Ford and GM applications as well.

The lines that came with worked fine, I removed the pressure line from my power steering box and pump, put hydroboost lines in its place and connected them to the proper place on the booster. For the return I cut and put a T in the return line and clamped everything.

I have completed my hydroboost conversion, all I can say is WOW, and I also upgraded to the chevy rear wheel cylinders as well. I just put on 35x12.5 tires all at the same time and the truck still stops better. I am at $425 for the parts.

A few people at SOP wanted the applications I used and some basic instructions.

First I got a junk yard hydroboost unit for a 1990 1 ton chevy c/k30. You will need a junkyard unit for the core, the internal spring mechanism, and the mounting bracket. 60$

Then from napa I ordered a new hydroboost unit for the same application, I also ordered all the hoses for the same application. 250$

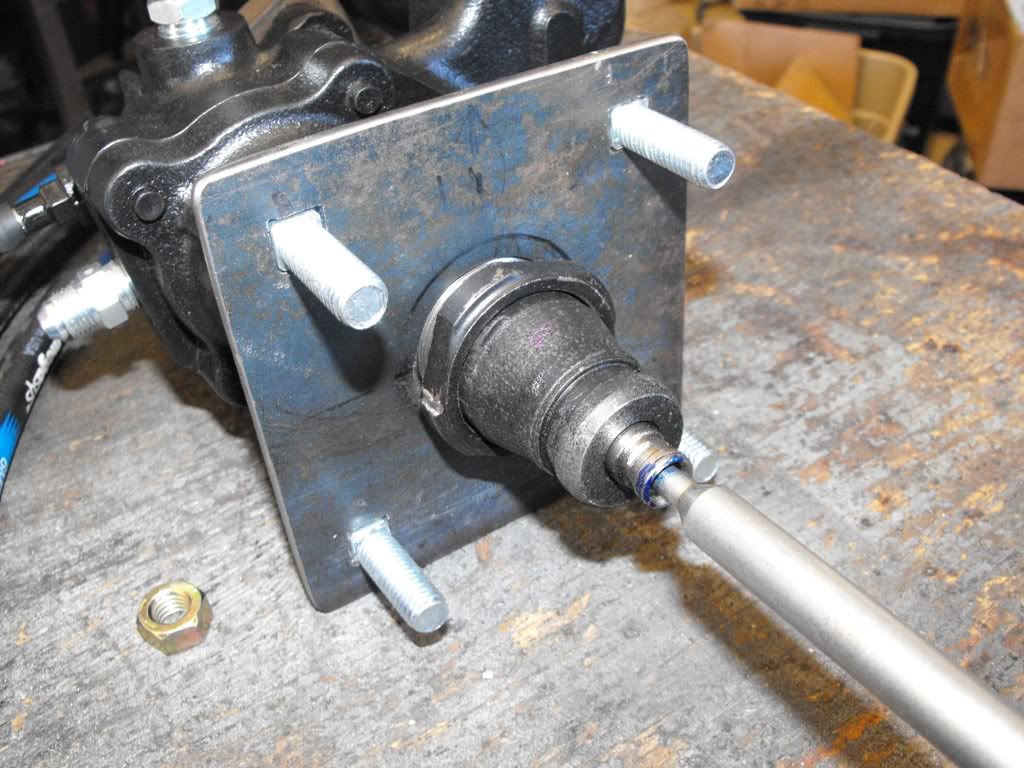

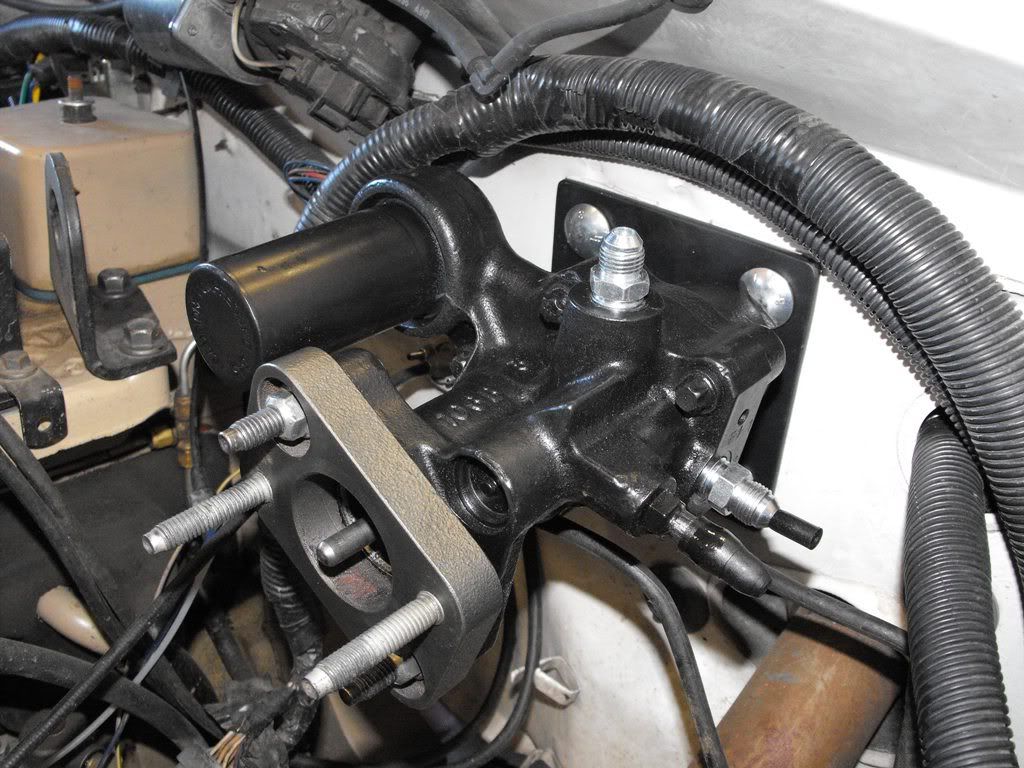

Two holes in the mounting bracket are the same as the Dodge vacuum boosters, two new holes will need to be drilled in the firewall. Weld (4) 3/8" x about 2" long bolts to the chevy square bracket (this is optional but makes slipping the bushings on later much easier. The hydro booster requires a large square socket which we made from some tubing. There is a small bracket that supports the lines which hangs from the master cylinder bolts, the oval holes will need to be widened slightly this can be done with a die grinder or round file.

I choose NOT to modify the push rod, it need to be shortened about

1 5/16", so I made aluminum spacers to move the booster farther into the engine compartment. Why? Well this makes spare parts much easier to get in the future. I had no clearance problems with the cooler tubes. I also needed a small bushing to adapt the GM rod end to the dodge pin, .503" id .568" od. I supposed one could have drilled out the brake side of things and put in a larger pin. Remove the rubber boot and foam spacer from the junkyard booster and slide it over the push rod before sliding the it through the firewall. Some thick HDPE foam cut to fit would have been great here.

The dodge master cylinder will not work with the chevy hydrobooster, the end configuration is slightly different. So with some careful research on Autozone online I ended up getting a 1991 chevy k30 (1 ton) master cylinder with heavy duty brake option "JB8 hydroboost" I got this part from Autozone new with no core and reservoir. This has the same size fittings as stock dodge with a 1.250" bore. I am not sure if a hydroboost unit from this application would fit our trucks. $90

The final piece of the puzzle was the 2000 dodge power steering pump I acquired from eBay. This unit had an additional return, has larger internal bearings and will bolt to our vacuum pump, use locktite on the 10mm studs and nuts! $25

You will also need some plastic tube adapters to change the vacuum line connection that feeds the dash vents and cruise, this was minor just some tube adapters I had lying around.

As many have said this was one of the best mods for my truck. and it nearly looks factory done with all of the shelf parts, in a pinch the truck could be returned to vacuum brakes as well.

It's not, there's 3 hydraulic hoses, disconnect the one from the power steering pump to the steering box. Hook the 1 hose up directly from the hydro boost unit to the pump, the other hose goes to the steering box and the last one is returned to the reservoir.

They work better because they use hydraulic pressure as opposed to vacuum. I went from standing on the brake pedal to stop to just setting my foot on it.

Hydroboost unit and master cylinder out of 1993 chevy 1 ton van----$90

Napa hose 7-2245 pump to hydroboost. $28

Napa hose 7-2246

Napa hose 7-2662

I used only 1 of the other 2 hoses. It was the pressure hose from the hydroboost to the power steering. I used 3/8" hose for the returns. It was $27.

I had to make a plate for the hydroboost to bolt to the firewall, and swap rod ends & adjust length.

I have access to a hydroboost unit with Master cylinder from a 2003 Chevrolet 1 ton truck. The reason I want to use this unit is because these trucks have 4 wheel disc brakes, and my truck also has 4 wheel disc brakes. Since I will get the hydroboost and master cylinder assy, I was assuming it would all be compatible. For those of you guys that have done this conversion, what else will I need to do other than fabricating a mounting bracket/plate to mount it to the firewall at the correct spacing distance and clocking? Do I also just need to T into the pressure line coming from the power steering pump, and also T into the return line?

You can't T the pressure side, the hydroboost needs to get pressure first, then there's a pressure line that runs the power steering unit. There's a priority valve in the hydroboost unit that sends pressure to the power steering unit while you're braking. A T in the return line will work just fine.

You want to look for a pump from a GMC 3500 HD that came with the hydroboost from the factory. It will have the correct output pressure plus the reservoir with the double return. Press the pulley off and press the Cummins adaptor on and you're off and running. Bolts right up.

Dodge master cylinder will not work with the Chevy hydrobooster

That's all for now. I'll update with pics and more tech data, and my own actual conversion soonest.

- M2

For this article I'll presume the truck being upgraded is a 72-93 Dodge/plymouth. Now, I haven't actually done this conversion, yet, but it's in the works. So while I cannot guarantee everything will work exactly as it is writen here I'm reasonably sure those that have done this in the past (and where I got this info from in the first place) will say it does in deed work like a champ.

First off, hydroboost systems are not a custom aftermarket item - they are factory braking systems on many 90s and newer Chevy trucks and if I understand right many later 2nd gen Dodge trucks 97? and up.

Alright, so what is hydroboost? Very simply it is hydraulic brakes, using pressure from the power steering pump. Our trucks come with vacuum-assist brakes via the brake booster - well the hydroboost unit essentially replaces the vacuum booster. The typical net effect is an increase in braking pressure, sometimes dramatic, resulting in a large increase in braking. Most folks that convert over from vacuum report decreased pedal effort and very good braking - not something we often hear about from a big heavy Dodge.

The drawback is, the power for your brakes comes from your power steering pump - so long as your pump is operating you will have power. Lose the belt for it and you full-Flintstone for your brakes. The diesel guys have the bonus because the power steering pump is gear-driven off the engine, so as long as the engine is running you gots brakes.

For the purposes of conversions, the best overall system seems to be using a complete Chevy hydrobooster/master cylinder system, with the newer Dodge power steering pump.

- HOW IT WORKS -

Dodge power steering pump sends hydraulic hi-pressure to the Chevy hydrobooster brake unit, then the hi-pressure returns from the HB unit to the Dodge power steering box. Both systems get full hydraulic hi-pressure, and those lines must be rated for hi hydraulic power steering pump pressure.

The hydroboost unit and the power steering unit both require return lines, both low pressure, and those two lines can be tee-d into each other and run back to the power steering pump.

That's the bolt-up stuff; now for the voodoo.

The Chevy and Dodge hydroboost units do not bolt up to the 1st gen Dodge firewalls - an adaptor plate must be made. The only reference I have for this is from other sources at DTR, 1stGen, and I'll post up those pics as soon as I am able. As well, I plan to install the HB system in my own rig, and I will do a full write-up when I do, hopefully by Aug 09 - a month from now.

Parts needed:

- Hydroboost unit - 1990 1 ton chevy c/k30 (You will need a junkyard unit for the core, the internal spring mechanism, and the mounting bracket)

- Master cylinder - 1991 chevy k30 (1 ton) with heavy duty brake option "JB8 hydroboost"

- Power steering pump - 2000 dodge power steering pump - this unit had an additional return, has larger internal bearings and will bolt to our vacuum pump, use locktite on the 10mm studs and nuts!

For you 4-wheel disc troops, use the following HB unit and m-cylinder -

- 2003 Chevrolet 1 ton truck

**************************************************************

The following is a list of exerpts from various websites - I used these to generate the how-to thus far.

The lower relief pressure on the OE pump won't hurt anything in normal operation, the booster just won't produce as much boost at the top end. As long as you have enough pressure output from the M/C to drive the front wheels to lock you're ok. Where you might want the extra pressure would be if you had some mondo big tires or were loaded really heavy.

From what I understand, all hydroboosts are basically the same with the exception of some changes to the spool and pilot valves which control sensitivity and apply rates. Also the size of the accumulator (this holds pressure to give assist if the engine quits) varies depending on who the unit was sold to. The things that very per OE application are the mounting plate that clocks the unit on the fire wall, the stud spacing on the M/C end, the input rod length and pin diameter and sometimes the hose fittings. Since it's a custom install that needs fabrication anyway, dealing with this stuff is not too hard. I would suggest that when you source one, either new or used that you get the M/C that corresponds to the application that the booster comes from. That way the stud spacing and pin depth will match. Be aware that the second gen Dodge booster requires a spacer plate on the booster output end to correctly clock the M/C. I don't know if this is true for the Ford and GM applications as well.

The lines that came with worked fine, I removed the pressure line from my power steering box and pump, put hydroboost lines in its place and connected them to the proper place on the booster. For the return I cut and put a T in the return line and clamped everything.

I have completed my hydroboost conversion, all I can say is WOW, and I also upgraded to the chevy rear wheel cylinders as well. I just put on 35x12.5 tires all at the same time and the truck still stops better. I am at $425 for the parts.

A few people at SOP wanted the applications I used and some basic instructions.

First I got a junk yard hydroboost unit for a 1990 1 ton chevy c/k30. You will need a junkyard unit for the core, the internal spring mechanism, and the mounting bracket. 60$

Then from napa I ordered a new hydroboost unit for the same application, I also ordered all the hoses for the same application. 250$

Two holes in the mounting bracket are the same as the Dodge vacuum boosters, two new holes will need to be drilled in the firewall. Weld (4) 3/8" x about 2" long bolts to the chevy square bracket (this is optional but makes slipping the bushings on later much easier. The hydro booster requires a large square socket which we made from some tubing. There is a small bracket that supports the lines which hangs from the master cylinder bolts, the oval holes will need to be widened slightly this can be done with a die grinder or round file.

I choose NOT to modify the push rod, it need to be shortened about

1 5/16", so I made aluminum spacers to move the booster farther into the engine compartment. Why? Well this makes spare parts much easier to get in the future. I had no clearance problems with the cooler tubes. I also needed a small bushing to adapt the GM rod end to the dodge pin, .503" id .568" od. I supposed one could have drilled out the brake side of things and put in a larger pin. Remove the rubber boot and foam spacer from the junkyard booster and slide it over the push rod before sliding the it through the firewall. Some thick HDPE foam cut to fit would have been great here.

The dodge master cylinder will not work with the chevy hydrobooster, the end configuration is slightly different. So with some careful research on Autozone online I ended up getting a 1991 chevy k30 (1 ton) master cylinder with heavy duty brake option "JB8 hydroboost" I got this part from Autozone new with no core and reservoir. This has the same size fittings as stock dodge with a 1.250" bore. I am not sure if a hydroboost unit from this application would fit our trucks. $90

The final piece of the puzzle was the 2000 dodge power steering pump I acquired from eBay. This unit had an additional return, has larger internal bearings and will bolt to our vacuum pump, use locktite on the 10mm studs and nuts! $25

You will also need some plastic tube adapters to change the vacuum line connection that feeds the dash vents and cruise, this was minor just some tube adapters I had lying around.

As many have said this was one of the best mods for my truck. and it nearly looks factory done with all of the shelf parts, in a pinch the truck could be returned to vacuum brakes as well.

It's not, there's 3 hydraulic hoses, disconnect the one from the power steering pump to the steering box. Hook the 1 hose up directly from the hydro boost unit to the pump, the other hose goes to the steering box and the last one is returned to the reservoir.

They work better because they use hydraulic pressure as opposed to vacuum. I went from standing on the brake pedal to stop to just setting my foot on it.

Hydroboost unit and master cylinder out of 1993 chevy 1 ton van----$90

Napa hose 7-2245 pump to hydroboost. $28

Napa hose 7-2246

Napa hose 7-2662

I used only 1 of the other 2 hoses. It was the pressure hose from the hydroboost to the power steering. I used 3/8" hose for the returns. It was $27.

I had to make a plate for the hydroboost to bolt to the firewall, and swap rod ends & adjust length.

I have access to a hydroboost unit with Master cylinder from a 2003 Chevrolet 1 ton truck. The reason I want to use this unit is because these trucks have 4 wheel disc brakes, and my truck also has 4 wheel disc brakes. Since I will get the hydroboost and master cylinder assy, I was assuming it would all be compatible. For those of you guys that have done this conversion, what else will I need to do other than fabricating a mounting bracket/plate to mount it to the firewall at the correct spacing distance and clocking? Do I also just need to T into the pressure line coming from the power steering pump, and also T into the return line?

You can't T the pressure side, the hydroboost needs to get pressure first, then there's a pressure line that runs the power steering unit. There's a priority valve in the hydroboost unit that sends pressure to the power steering unit while you're braking. A T in the return line will work just fine.

You want to look for a pump from a GMC 3500 HD that came with the hydroboost from the factory. It will have the correct output pressure plus the reservoir with the double return. Press the pulley off and press the Cummins adaptor on and you're off and running. Bolts right up.

Dodge master cylinder will not work with the Chevy hydrobooster

That's all for now. I'll update with pics and more tech data, and my own actual conversion soonest.

- M2